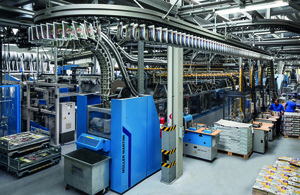

“We made a smart investment in 2002,” says Max Rindlisbacher. “Our mailroom has proved itself and still absolutely satisfies our requirements – especially as newspapers are not a growth market.” Nevertheless, the Head of Production and Facility Management at Tagblatt Medien in St. Gallen has no doubts that “a mailroom needs to be brought up to date in the middle of its economic life-time”.

Software Elements Require Updates

One reason is that certain parts wear out with time. The other is that not all components are still available for aging control modules. “Modern machine generations have considerably more software elements, which necessitating regular updates.” says Rindlisbacher.“That applies both to printing presses and to print finishing.”

A retrofit program is the obvious choice instead of a new investment for economic reasons alone. “Ultimately a mailroom is not a cell phone that you change every three years, but a major investment that is amortized over many years, not to mention the complexity of replacing existing machinery from a production perspective,” says Rindlisbacher.

Overhaul at the Muller Martini Factory

After a number of control and operating system components were modernized in 2007 and modifications were made to the chains and rails of the NewsGrip/NewsLiner, it was the turn of the first NewsLiner feeders this year. Four feeders were completely reconditioned at the Muller Martini factory in Zofingen. “The remaining six will follow in 2013 and 2014,” explains Stefan Kocher, Product Manager of the Muller Martini Service Program/Head of Support.

He has been in touch with Rindlisbacher for some time to clarify in detail the retrofit needs of the mailroom in St. Gallen. “Naturally we have our standardized MMServices catalog, but an individually tailored service program is indispensable for complex newspaper mailroom systems,” says Kocher.

Rindlisbacher also regards that as imperative. “It’s important for us, the users of the machinery, to sit down with the manufacturer and analyze the current weaknesses and then introduce the necessary measures together.”

High Availability is Paramount

According to Rindlisbacher, the latest updates and upgrades have two objectives: “In the medium and long term we want to keep using these machines for a further eight to ten years. In the short term we need to ensure their availability day in, day out. That’s vital for a newspaper printer. We can’t risk a crash of our systems.”

For that reason, as both Rindlisbacher and Kocher underline, the primary aim of the mailroom retrofits is stability of the systems, rather than higher performance. “However, a certain increase in efficiency can also be achieved with upgrades,” says Kocher.

Regular Maintenance Makes Retrofit Easier

To ensure stability, Rindlisbacher attaches great importance to periodic replacement of wear parts and sensible replacement parts storage, as well as observation of the maintenance concept. The individual elements are cleaned and overhauled weekly, monthly, quarterly or half-yearly. “That makes a retrofit much simpler,” says Rindlisbacher, who has worked for Tagblatt Medien for 25 years and knew the predecessor mailroom from Muller Martini that was in operation in St. Gallen from 1985 to 2002 inside out.

The results of that maintenance philosophy are impressive: in ten years the St. Gallen mailroom has not experienced a single major system failure and newspaper production has been ensured at all times.

Retrofit Stages in the St. Gallen Mailroom

Installation

- 2002: 2 NewsLiners, 2 NewsGrips, 6 PrintStack CN 80s, 2 FlexiRoll buffers, 6 TABA IS top sheet feeders, 6 Imaje inkjet printers, 6 SMB strapping units, a ramp system, 2 three-fold lines with addressing system, top sheet feeder and integrated stack formation.

Retrofit

- 2007 Ramp: Modernization of hardware/software.

- 2009 Ramp Control System: Upgrade to Mailroom Production Control (MPC).

- 2009 NewsGrip/NewsLiner Chains and Rails: Training by Muller Martini, modifications by St. Galler Tagblatt.

- 2011 PC FlexiRoll: Operating system upgrade to Win XP Embedded.

- 2012 Feeder Retrofit: 4 peel-off feeders (main product/preprinted section) were reconditioned in the factory.

- 2012 PrintStack CN 80 Control Retrofit: Pilot project conversion of control to B&R.