That is precisely what has happened at the printing center of the Münchner Merkur tz media group in Munich. A first-generation NewsLiner with five feeders has been in operation at the main plant of the Bavarian newspaper publishing company in Dessauerstrasse since 2000. It was extended to include a CoLiner, which provides an additional six feeders, a few weeks ago. The complete system now has a total of eleven feeders, which means that the Munich-based media group is ideally equipped to handle the increase in insert volume that the company has experienced in recent years, especially with respect to advertising papers. “We can now process the various newspaper titles more quickly and with a higher degree of automation, making production more cost-effective. What’s more, we can also perform more insert splits than before,” says Managing Director Uwe Günther.

The Münchner Merkur tz media group in Munich produces two daily newspapers – the Münchner Merkur with 20 regional editions and a total run size of around 150,000 copies and the TZ with a run size of 170,000 copies on weekdays and 210,000 copies at weekends. In addition, 15 weekly newspapers are printed with a total run size of around 1.8 million copies. The daily newspapers have between three and seven inserts, and the new system often runs at full capacity when processing the weekly newspapers.

According to Uwe Günther, the project to extend the inserting system went as planned, with virtually no glitches. “In terms of hardware, everything was right from the start. A few adjustments needed to be made initially to the newly developed software, but Muller Martini quickly took care of that.”

The latest CoLiner is the third mailroom investment of the Münchner Merkur tz media group within two years. A complete Muller Martini system with two ProLiners and two CoLiners, three compensating stackers and a comprehensive ramp system was installed at the newly built Penzberg printing center in 2013. A Proliner with a CoLiner and an integrated ProStitch stitching unit, which, in conjunction with the NewsTrim fanflex trimmer, enables inserting, stitching and trimming to be performed inline, was commissioned in Munich in the first half of 2015. “We believe in the future of printed newspapers,” says Uwe Günther, explaining the major investments of the long-established company.

(http://www.mullermartini.com)

The CoLiner Meets an Old NewsLiner

The CoLiner Meets an Old NewsLiner

Article ID:

19645

25.02.2015 – Even a decade and a half after commissioning, Muller Martini systems can be connected with the latest unit to enable customers to respond to current market requirements with the aid of an upgraded complete system. The CoLiner pre-gathering unit, for example, can be docked onto the NewsLiner newspaper inserting system.

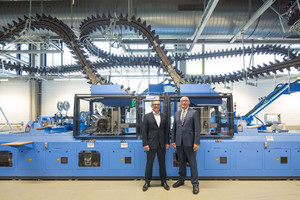

Uwe Günther (left), Managing Director of the Münchner Merkur tz media group: “We can now process the various newspaper titles more quickly and with a higher degree of automation, making production more cost-effective.” Right: Reinhold Achtner, Sales Manager at Muller Martini Germany.

Related Articles

-

2020-10-15 11:21

-

2020-10-08 10:36

-

2020-09-29 17:42

-

2020-09-29 17:24

-

2020-09-29 10:57