Specialized in newspapers and freesheets

Nearly all of the printing center’s capacity is taken up by the publisher’s own products, namely part editions of the dailies Münchner Merkur and tz (13 subeditions with approximately 90,000 newspapers per day) as well as some 30 different freesheets for the southern Upper Bavaria region amounting to 1.6 million copies a week.

The printer gets through 35,000 plates in 345 x 538 format per month on average during the production of these newspapers and freesheets on a KBA Commander CL web press with five four-high towers and two folders. The plates are made on two Agfa violet CTP systems with clean-out units directly downstream. The negative working KODAK LIBRA VP Plate is currently processed on one of these two CTP lines.

“We conducted the first tests with the Kodak violet plate in September 2016 because we were looking for an alternative for a second plate brand. Our platemaking and production tests showed it to be reliable and stable from the outset, and following the trial period we increased the LIBRA VP Plate delivery quantities. We obviously attached priority to an environmentally friendly plate that we could process using a simple easy chem system in our existing clean-out units and that didn’t need any water for rinsing,” Kasdorf reports. “We used to work with a single plate type, which we alternated in three-month cycles, but since the start of 2017 we’ve been producing continuously with the LIBRA VP Plate on one of our two CTP line.s” As a relatively high-resolution newspaper printing plate, the LIBRA VP Plate is suitable for imaging with AM linescreens up to 150 lpi or up to 180 lpi hybrid. The printing center in Penzberg employs a conventional 120 lpi screen for all products.

Compatible with the existing prepress technology

Kasdorf confirms the total lack of teething troubles when the LIBRA VP Plate was first introduced: “Kodak offered to send a plate specialist to support us straight away. Only very minor adjustments were necessary to the platesetter settings during the half-day he spent here. Nothing at all had to be modified on the clean-out unit in preparation for the easy chem clean-out finishing process. And as far as plate throughput is concerned, we haven’t noticed any difference between the LIBRA VP Plate and the other plate we use.”

According to the manufacturer, the press can keep going with run lengths of up to 300,000 impressions when KODAK LIBRA VP Plates are processed in an easy chem system with clean-out finisher. However, the Penzberg facility never has to print anything like this six-figure volume. Around 90,000 impressions is the maximum the plates are expected to achieve, so that the LIBRA VP Plate is by no means pushed even close to the limit.

“The LIBRA VP Plate fits perfectly into our production workflows,” Kasdorf concludes. “Kodak delivers promptly and is absolutely reliable. There are no visible product variations from one batch to the next. And if ever we have any technical questions, Kodak has some very competent experts to advise us.”

(end)

(http://www.kodak.com)

Libra VP: One that fits

Libra VP: One that fits

Article ID:

21315

At the Penzberg printing center of the Münchner merkur / tz media group, the Kodak Libra VP Digital Plate fits seamlessly into efficient, high quality newspaper production workflows

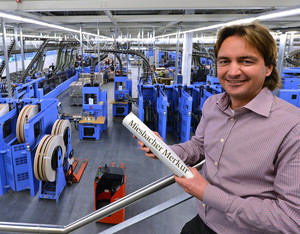

10.10.2017 – “We operate a strict multi-supplier strategy when it comes to plates, and the Libra VP Plate from Kodak has meanwhile replaced another manufacturer’s violet offset plate in the wake of various experiences,” explains Christian Kasdorf, Operations Manager at Druckzentrum Penzberg GmbH & Co. KG. The printing center is situated in Penzberg, a small town about 30 miles south of Munich (Germany); it belongs to the Münchner Merkur / tz media group and is housed in a new building that was only opened in February 2013 on a greenfield site.

Christian Kasdorf, Operations Manager at Druckzentrum Penzberg GmbH & Co. KG, has been employed at Münchner Merkur / tz media group since 2007.

Attachments

Related Articles

-

2020-10-15 11:21

-

2020-10-08 10:36

-

2020-09-29 17:42

-

2020-09-29 17:24

-

2020-09-29 10:57