With the completion of the second installation phase, Thairath Daily has now successfully concluded the conversion to CTP. Two brand new NELA VCPevolution Vision punch/benders, which are connected to three CTP lines, now make the system complete. An identical line with three CTP lines and two NELA punch/benders had already been in production before.

Each NELA VCP delivers 270 panoramic plates per hour, which are stored in two 6-bin sorting stackers. All plates dedicated to the same press tower are sorted into one stacker bin. “After we completed the installation and put it in full production”, says Mr. Thanin Teranasarn of Thairath Daily, “plate quality improved and we reduced the time of the plate making process. This makes our whole workflow even more flexible.”

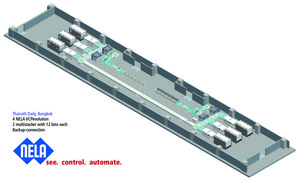

The completed NELA system impresses by its sheer dimensions: a 32 meter-long plate conveyor connection between the two CTP systems, which are separated by a glass wall, provides an absolutely secure back-up.

All NELA Vision punch/benders feature the PQM+-system, which automatically measures the image quality of each individual printing plate and triggers ejection of bad plates. It guarantees that only plates with perfect image quality are supplied to the press. The tool allows monitoring and reproducing the quality of plate production according to ISO-norms, at any time during the production process.

With the start-up of the new lines at Thairath Daily, NELA celebrates its largest installation in Asia: A success story that began at DRUPA 2008 with an agreement over the supply of the two NELA systems, with an option for even two more lines. A visit to the NELA factory in Lahr, Germany, had turned the balance for NELA equipment. Says Thanin Teranasarn: “At Thairath our main focus is on equipment quality. We were even more confident about our decision for NELA products, especially the VCPevolution, after we had visited the NELA factory.”

About NELA: NELA forms the largest register control and plate automation company in the printing industry. The 3rd generation, family-owned company employs more than 200 employees worldwide with manufacturing facilities in Germany and USA plus sales offices in Singapore and Taiwan. With more than 1,700 Vision PunchBender systems installed worldwide, NELA is the leading technologist in the world and a state-of-the-art manufacturer in plate automation and register systems.

Largest NELA in-line Plate Production System installed in Asia

Largest NELA in-line Plate Production System installed in Asia

Article ID:

13215

Lahr, Germany, 18 April 2011 – NELA is proud to announce that it has finished installing the largest fully automatic printing plate production line in Asia in December, 2010. At Bangkok’s Thairath Daily, a total of 4 VCPevolution Vision punch/benders deliver ready-to-print offset plates for the manroland Press.

Attachments

Related Articles

-

2020-10-15 10:21

-

2020-10-15 09:50

-

2020-10-15 08:21

-

2020-10-14 10:49

-

2020-10-12 09:49