Pratim Dutta, Sr. Manager Sourcing, ABP Pvt. Ltd.Significant quantities of waste are generated during printing process, CTP operations and finishing, like waste paper, used inks, empty chemical containers, used blankets, non-newsprint wastes and waste water including several other items.

Pratim Dutta, Sr. Manager Sourcing, ABP Pvt. Ltd.Significant quantities of waste are generated during printing process, CTP operations and finishing, like waste paper, used inks, empty chemical containers, used blankets, non-newsprint wastes and waste water including several other items.

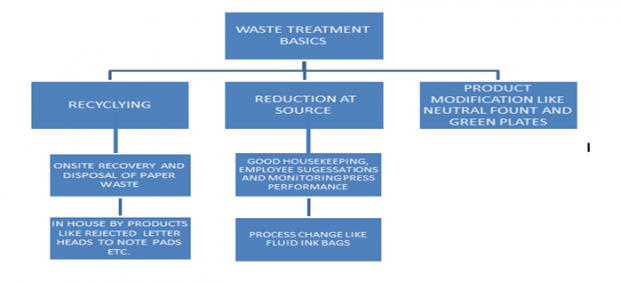

Most of paper wastes like printed waste, reel opening, reel ends, paper sweeping, paper cores are recyclable in nature. ABP objective is not only reducing these wastes, also encourage recycling paper wastes through approved recyclers.. Good neatness is the key to proper waste treatment and disposal e.g. All paper wastes generated in plant are disposed for being recycled by approved newsprint manufacturer, making of exercise books, used for packing etc..

Any extra paper generated, before disposing, we look into opportunity of making notepads for internal uses. Our effort is to continuously monitor press performance to minimize bad runs and waste. ABP, meets the challenge in using full 40 GSM at speed of 84K+CPH to keep printed waste generation at less than 0.8%. Total waste generated is less than 2.5%. This proofs our focus on total waste control objective.

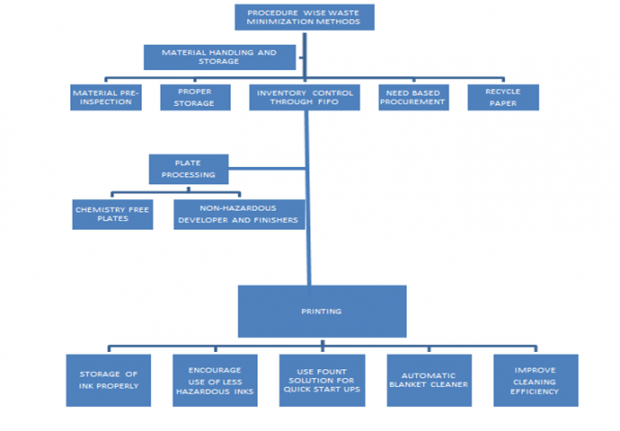

With regard to other form of wastes, ink waste , chemical waste including water waste-resulting from image processing, plate making also reducing developer and finisher use, objective is to control such so that it benefits the organization by reducing chemical raw material needs and obligations associated with hazardous waste disposals. Classic example being, usage of low Chem & chemistry free Green Plates, where disposal of hazardous developer and plate finisher is reduced to nearly negligible.

Another one of its kind is usage of fluid bags in place of ink silos which reduces the wastage of ink from 2.5% to 0.6%, because unlike silos there is very little left over ink as we can squeeze out the entire ink from the fluid bags thereby reducing waste generation and cleaning is not required, as like silos we have to clean the left over dried inks thoroughly for re-use, we need to incinerate the inner part of fluid bags by authorized vendor of Pollution Control and re-use the outer layer for multiple times. Here the transport cost of Metallic silo can also be saved which has impact on the total ink cost.

Another salient feature of press chemical is the Neutral Fount Solution in place of Acidic, which is ecofriendly and required less water for printing which saves almost 20-25% of total water usage, the exquisiteness of Neutral Fount is pH 7.0, and like water which saves the valuable press life by reducing the corrosion. We are also in a process to develop mild acidic Fount for UV printing which require compulsorily acidic Fount. But we are trying to get rid of Acid from Printing.

Waste treatment basics

Waste treatment basics

Needless to say, Inks and paper are the principal raw material used in printing process. Some other chemicals like blanket wash, plate making items, fount solution, lubricating oils, cleaning solvents are also required. Used Inks and oils, fount solution and solvent jars, represent Hazardous wastes.

Hazardous waste reduction efforts in ABP are emphasized to each employee, across the organization. Employee suggestions are being encouraged. Proper discrimination of wastes raises proper recyclability and good market rates. We keep proper record of inventory, Implement FIFO for usage of chemicals. Designated store operator is usually assigned to manage raw materials for proper inventory control and to ensure hazardous substances are properly controlled, labeled and a Material Safety Data Sheet (MSDS) is on file for all.

Our procurement team and inventory control team work together to ensure we do not order more than can be used within the shelf life of the product. We label stocks and expiration dates properly and make them readable. We at ABP always ensure in due discussion with production representatives, If any materials, chemicals have exceeded their shelf life, check on alternative uses before discarding.

Hazardous wastes and its disposal is taking place, under valid agreement between ABP & Recycling Agent West Bengal Waste Management Limited, approved by SPCB (WBPCB).

As a Publication house, we pioneered Hazardous Waste Management in West Bengal, approved by West Bengal Pollution Control Board in Sept 2011. As hazardous waste generating and recycling units we are required to submit manifest copies Form 13 regularly to the Board showing each movement of hazardous waste for recycling or disposal.

We are also mandated to submit Annual Returns in Form 4 on hazardous waste generation, recycling and disposal to the Board within June every year. In addition to Form 4, as recyclers of hazardous wastes we are also required to submit annual return on hazardous waste collected and recycled in Form 6 .

Pollution Control Board, obtains similar copies from approved recyclers for cross checking and make periodical surprise visits to and even approved recyclers location for ensuring all compliances are being met up with. We regularly display stock of Hazardous waste in our plant at on a display board naming “ENVIRONMENTAL INFORMATION”.

Through our approved recycler, we periodically obtain test reports of Comprehensive Analysis of hazardous waste generating from plant as per rules of Ministry of Environment and Forests, Central Pollution Control Board and West Bengal Pollution Control Board, agreement between ABP & West Bengal Waste Management Ltd. The comprehensive analysis done for Hazardous waste characterizes its respective disposal pathway, recyclable or direct Incineration depending on the chemical characteristics, our used ink, used oil and ink disposal bags are characterized in Disposal Pathway of West Bengal Waste Management Ltd as Direct Incineration, and we act accordingly.

At present there are more than nine hundred (900) nos. hazardous waste generating units in the State of West Bengal like ABP Barsat and One Common Hazardous Waste Treatment, Storage and Disposal Facility (CHWTSDF) located Haldia, Purba Medinipur that caters to all units in the state.

CHWTSDF has an incinerator, a secured landfill site, waste stabilization unit, temporary waste storage sheds, vehicle wash area and a well-equipped laboratory.

E-Waste management in ABP, with rapid technology change, increased consumer electronics purchase, more E-Waste is generated and more hazardous landfills is happening, which is in turn increasing human health and environmental risks. E-waste in ABP is accumulated in proper bins earmarked for storing E-waste. To confirm to Environmental regulations, ABP is tied up with India’s largest electronic asset management company, Attero who promotes eco-friendly reuse and recycling of electronics in an environmentally responsible manner.

They provide DESTRUCTION CERTIFICATE against every lifting as confirmation of complete eco-friendly disposal of E Wastes.

Waste minimisation methods

Waste minimisation methods

Finally at ABP, we follow Procedure wise Waste Minimization methods, SLOGAN IS “GO GREEN-KEEP OUR PLANTS CLEAN”.