About this project

Mechanical audit of printing presses helps to identify your press condition and enables you to act on time to sustain machine efficiency thereby save cost. This project uses basic conditionmonitoring techniques such as vibration analysis, ultrasound analysis and thermographic imaging analysis to measure the health condition of your printing machine.

WAN-IFRA’s Research and Material T esting Center (RMTC) in collaboration with pme maurer GmbH, Germany has carried out several audits in many printing plants in the last 3 years. This service has shown proven results and could bring immense benefits to newspaper printers at large.

Why mechanical audit for printing presses

Printing press is the heart of any newspaper company and any initiative to extend its service life is of great importance. Mechanical audit project helps you in improving the service life of the printing press by analysing the condition of critical parts of the machine.

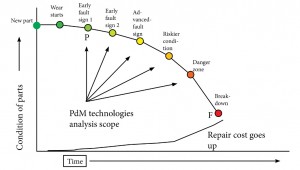

Fault sign starts to appear in proactive or predictive domain of a mechanical part which could grow in magnitude over time and eventually fails if it is unnoticed or ignored.

Mechanical audit of the press plays a vital role in identifying these early fault signs and gives enough time to act on it thereby prolong the life of your printing press.

Benefits of mechanical audit

Mechanical audit helps to:

- Track the trend of mechanical wear of all critical parts.

- Replace the parts in severe condition immediately.

- Have planned replacement of expensive parts with preplanned budget.

- Run the machine in optimum energy consumption. Avoid paying for energy loss.

- Improve reliability by keeping your machine ideally to the original conditions.

- Extend service life with minimum budget.

Condition monitoring techniques

PF curvePredictive maintenance technologies used for condition monitoring tells you where you need to act exactly. There are several technologies available in the market for condition monitoring purpose. Any failure sign start with vibration, then leads to noise and causes elevated temperature, eventually it fails (ref PF curve image). Our auditing methodology of printing presses employes the basic technologies which are given below

PF curvePredictive maintenance technologies used for condition monitoring tells you where you need to act exactly. There are several technologies available in the market for condition monitoring purpose. Any failure sign start with vibration, then leads to noise and causes elevated temperature, eventually it fails (ref PF curve image). Our auditing methodology of printing presses employes the basic technologies which are given below

Vibration analysis

Mechanical vibrations in a machinery is common due to various dynamic forces, and mostly they are calculated frequencies allowed to some extent. Any uncalculated frquency due to wear and tear or misalignment or imbalance are completely unacceptable and reduces the service life of the mechanical systems.

The project measures vibration in all three axes which enable us to pin point the problem exactly. Whether its a new machine or into few years of service, vibration analysis helps to fix the issues at early stage.

Ultrasound analysis

In the process of mechanical system failure, prolonged vibration leads to noise generation. The generated noise is not audible to human ear, but an ultrasound instrument could receive these signals which could be analysed for the reason of failure. Not only the mechanical wear problems but also air leak, starvation of grease, electrical circuit issues also could be analysed in this way.

In the printing presses, problems are identified in the cylinder bearings, oscillator roller scratchings in the housing, clutch issues etc.,

Thermographical imaging

As mentioned, stages in the wear process is not explicit, unless otherwise it causes very frequent problems. Therefore, to look at the hidden problems, the mentioned special instruments are required.

Much worst situation could be like elevated temperature levels in the system. For example, lack of grease may increase the temperature and linear expansion of metals may cease the function or loose connection in a electrical fixture may cause fire accidents and so on.

But the temperature escalation is not visible, but through a IR camera, it is visible and obvious. In printing press audits, the project will identify reel brake temperature, bearing temperature, electrical connections etc.,

In a nutshell, ultimate aim of the mechanical audit is to act before a part fails, and reduce the repair cost to bring back the system to good condition and extend the service life of machine.

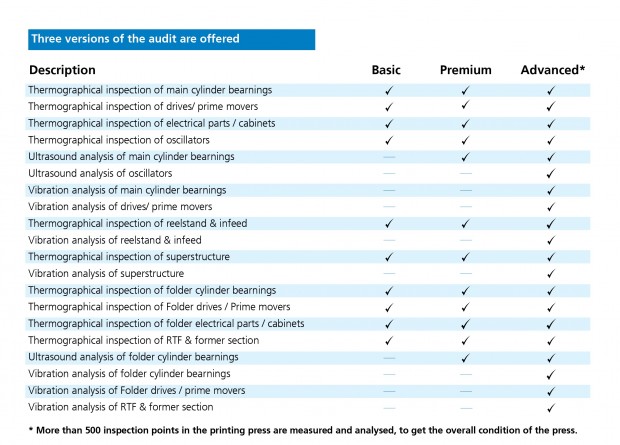

We offer flexible audit options

Project varients

Project varients

How we operate?

Project consists three phases.

Preliminary

• Discussion about machine configuration, production schedule, maintenance practices, any recurring problems and other machine related issues.

On-site inspection

• WAN-IFRA consultant visits your facility and carries out inspection in your press.

• On-site discussion about critical /dangerous problems.

Analysis reports, recommendations

• Analysis, reports and recommendations / remarks by our knowledge partner pme maurer GmbH.

• Post analysis support by WAN-IFRA and pme maurer

GmbH.

Fee for WAN-IFRA members

Basic : EUR 3,450 + + *

Premium : EUR 5,970 + + *

Advanced : EUR 10,722 + + *

* The fee given is for auditing a typical press configuration of 4 towers, 4 reelstands, 1 folder and superstructure.

* 18% GST to be added.

* Travel, accommodation, food and allowances for consultant/s are additional, will be charged on actuals.

Note:

- Press configuration varies with each printing plant. Therefore, for customised proposal please write to us.

- Non-members pay 35% more than the member price.

- Invoice will be in Indian currency (INR), based on the exchange price on the date of invoice.